Description

Agricultural Gloss Paint is a premium polyurethane-based, white spirit enamel formulated for versatile use across agricultural applications. Its durable, high-gloss finish is ideal for both new and refurbished machinery, equipment, and buildings, delivering long-lasting protection and an attractive appearance.

This robust gloss paint ensures excellent adhesion and durability on properly prepared surfaces, making it suitable for tractors, trailers, farm implements, and agricultural structures. The high-performance formula offers superior weather resistance and protection against wear and tear, ensuring your equipment looks great and performs reliably over time.

About This Item

- HIGH GLOSS FINISH: Provides a durable, high gloss surface that enhances the appearance of agricultural equipment and structures.

- WEATHER RESISTANT: Offers excellent protection against harsh weather conditions, including rain, UV exposure, and temperature fluctuations.

- FINISH: Gloss. For our Semi-gloss and Matt finishes click here.

- DRYING TIME: Touch dry in 2-4 hours, overcoat in 12-24 hours, full dry 7 days.

- COVERAGE: Approximately 8 square metres per litre. This does not account for the method of application, absorption of substrate or wastage.

- APPLICATION: Apply by brush or solvent-resistant medium pile rollers. This can aslo be sprayed.

- THINNERS: T0001 White Spirit.

- SHELF LIFE: 12 months.

Proudly manufactured in England by B.C. Paints Ltd. Please note that images and product titles are for advertising purposes only; tins are supplied in BC Paints logo cans or plain white cans for 0.5, 1, 2.5 and occasionally 5 litre sizes.

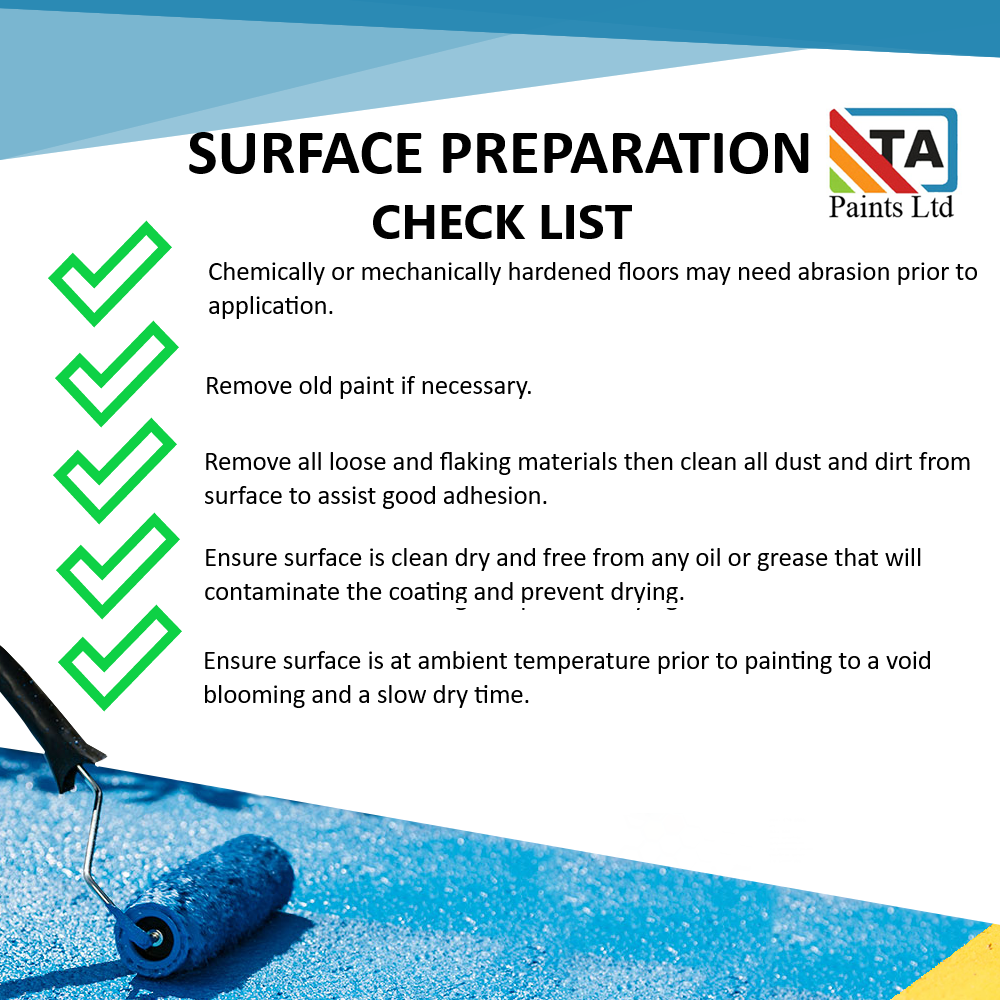

Application

Before starting, have your PPE ready, as our paint is oil-based and will not wash off easily with soap and water.

Ensure you have good ventilation to allow vapour to escape; ventilation is also necessary to maintain drying times. Without air movement, the coating won’t dry properly.

Be sure to stir the paint well before use.

Painting Over Existing Paint:

Step 1 - Preparation: Check the suitability of the product for the existing paint. We recommend trying a sample area first.

Step 2 - Clean and Abrade:

- Ensure the existing paint is in good condition prior to painting, then lightly abrade to provide a key for good intercoat adhesion.

- If there is flaking paint, it must be removed before painting.

- Ensure the substrate is dry and clean of any dirt, oil or grease.

Step 3 - Prime: This step is down to personal preference. Depending on the condition of the existing paint or if you are changing a dark colour to a light one, you may want to add one coat of primer.

If the material you are painting is fibreglass or metal and is showing you will need to spot prime with the appropriate primer. If there is rust this will need removing and spot priming.

Step 4 - Topcoat: Once you have completed the previous steps, 12-24 hours after applying the primer, you can add your first coat of topcoat. Wait another 12-24 hours before applying the second coat.

Painting bare Wood:

Step 1 - Clean and Prep: Ensure the substrate is dry and clean of any dirt, oil or grease. If there is any moisture in the substrate, it can cause delamination and lead to a loss of adhesion.

Step 2 -First Coat: Thin the first coat by 20% with T0001 White Spirit to ensure the paint impregnates the Wood, this will act as the primer/sealer.

Step 3 - Top coat: 12-24 hours after applying the first coat, you can apply the second coat of topcoat. Be sure to stir the paint well before use.

Painting bare Metal or Fibreglass.

Semi-gloss and Matt finishes have anti-corrosive properties, allowing them to be applied directly to metal. However, for complete protection, we recommend using a primer.

Step 1 - Clean and Prep: Ensure the substrate is dry and clean of any dirt, oil or grease. If there is any moisture on the substrate, it can cause delamination and lead to a loss of adhesion.

Step 2 - Prime:

Metal - If there is rust this will need removing and then priming with our High Build Zinc Phosphate Metal primer. If the substrate is exposed to harsh environmental factors, you can prime it with either Zinc Rich or our two-pack epoxy primer systems for optimal protection

Step 3 - Top coat: Wait 12-24 hours after applying the primer before applying the first coat of topcoat. Then, after another 12-24 hours, apply the second coat. Two coats of topcoat are recommended for optimal coverage.

Mixing

Always stir any paint well before use, as our coatings are heavily pigmented and separation can easily occur. You may experience colour float; for example, a green paint can appear blue before mixing. This is one of the reasons why mixing your paint before use is essential.

- Use a mixer on a slow-running drill or a palette knife on smaller cans to mix the paint. An egg whisk, screwdriver, or small stick that doesn’t reach the bottom of the can is insufficient for proper mixing.

- Mixing should take place for 3-5 minutes.

- If you are adding thinners; they will need to be added once stirred.

Paint mixers are available to purchase. Click here to buy one.

Spraying

Ensure you have the correct RPE, to protect against atomised particles that are being generated when spraying.

If applying with a pot gun:

Use a 1:2 to 1:4 tip setup and thin by 10% if required. More thinners may be added to achieve good atomisation and improve the flow of the paint, resulting in a better finish.

Air-assisted or Airless system:

Use an 11-13 thou tip (no thinners are usually required). If thinning is necessary, use around 10%. Set air and paint pressures until good atomisation is achieved and fingering (lines in the spray) have blended in.

Prime Colors

Clear Sealer, Gloss Black, Semi-Gloss Black, Matt Black, Gloss BS 00 A 05 Goosewing Grey, Gloss BS 00 A 09 Mid Grey, Gloss BS 10 C 31 Cream, Gloss BS 14 C 39 British Racing Green, Gloss BS 18 B 25 Grey, Gloss BS 18 E 53 Blue, Gloss BS 105 Blue, Gloss BS 106 Blue (Blue Black), Gloss BS 108 Blue, Gloss BS 224 Deep Bronze Green, Gloss BS 226 Middle Brunswick Green, Gloss BS 227 Deep Brunswick Green, Gloss RAL 5002 Blue, Gloss RAL 5010 Blue, Gloss RAL 5012 Blue Blue, Gloss RAL 5015 Sky Blue, Gloss RAL 5017 Blue, Gloss RAL 6011 Green, Gloss RAL 7024 Grey, Gloss Tile Red, Gloss White, Semi-Gloss White, Matt White, Gloss BS 04 E 53 Red, Gloss BS 08 E 51 Yellow, Gloss BS 538 Post Office Red, Gloss RAL 6018 Kawasaki Green, Gloss RAL 2004 Orange

Size

5 litre, 2.5 litre, 1 litre