Advice Line

Need more information about our products? Give us a call on 01902 954948 or email us at sales@taindustrialpaints.co.uk

Two Pack Epoxy Industrial Kitchen Floor Primers

2 Colour(s) Available

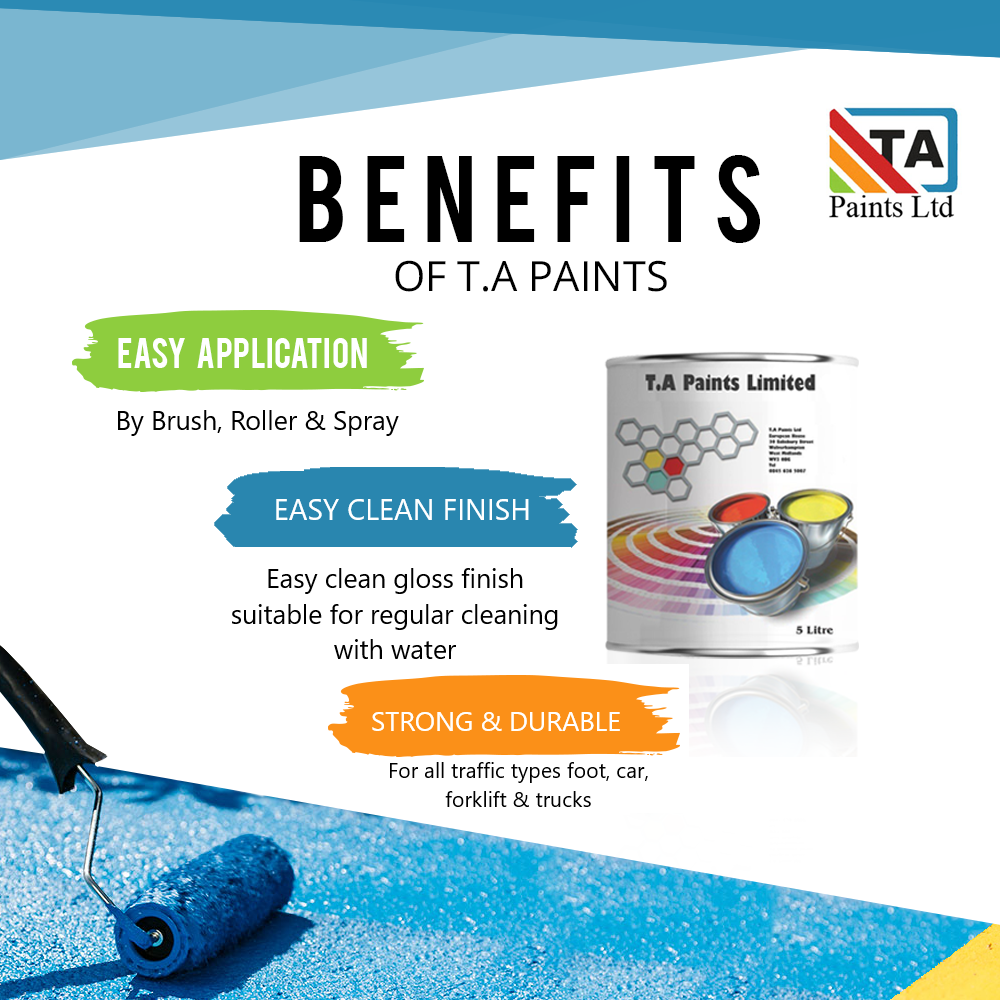

- Application By Brush Roller & Suitable Spray

- Heavy Duty For Heavy Traffic Inc Vehicles

- Suitable For Concrete Stone & Brick

- Walk On Dry Time as Little as 24 Hours

- Multi-Buy Discounts

- Free Delivery Available

- Regular price

- £85.99 Inc. VAT

- Sale price

- £85.99

- Regular price

-

- Unit price

- /per

Find Your Perfect Colour

Adding product to your cart

Advice Line

Need more information about our products? Give us a call on 01902 954948 or email us at sales@taindustrialpaints.co.uk

This product is not suitable for the following

- Tiles of any sort

- Unprimed plastic

- Bare aluminium (you will need a suitable etch primer)

- Untreated galvanised steel (Mordant solution first)

- A hot surface that reaches above 106 degrees (C) (you will need high temperature paints)

The colours shown on the images are for guidance only. The displayed colour will depend on your monitor and browsers. The finished colour therefore may not be as shown here.

All pictures are for illustration purpose only - 1 & 2.5 Litre cans are not screen-printed cans.

Description

Two Pack Epoxy is based on an epoxy resin that provides an excellent hard wearing coating once fully dry, with a mirror like gloss finish to concrete floors.

Please note although Epoxy coating’s offer the best chemical resistance and protection from the elements, the colours will chalk and fade in external applications.

Key Facts

Can be applied by brush & roller

Can be applied by brush & roller Minimal operation temperature is 10 degrees

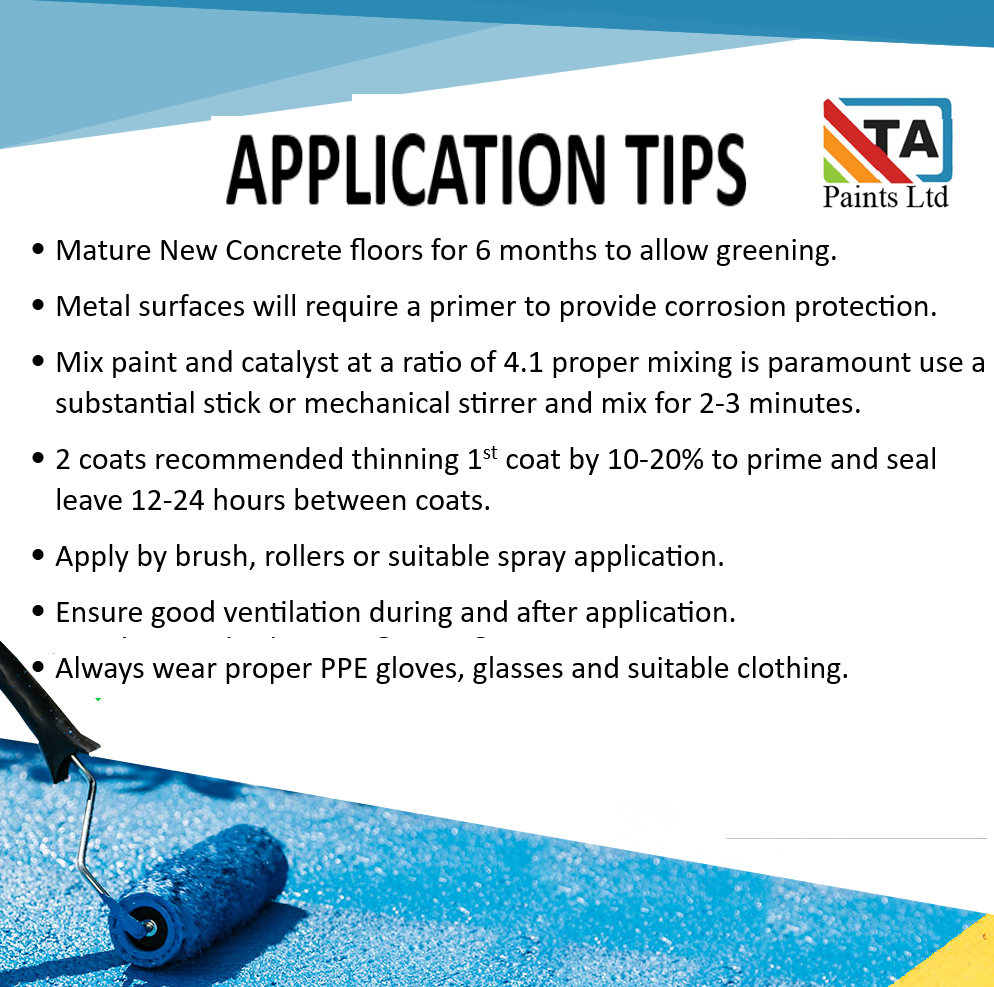

Minimal operation temperature is 10 degrees Mixing Ratio 4 parts paint to 1 part Catalyst

Mixing Ratio 4 parts paint to 1 part Catalyst

Once catalysed pot life of 2-3 hours

Once catalysed pot life of 2-3 hours

Do not pre seal the floor especially with latex or PVC sealers paint will not stick.

Do not pre seal the floor especially with latex or PVC sealers paint will not stick.

Easy Clean High Gloss Finish

Easy Clean High Gloss Finish

Touch Dry 2-4 hours

Touch Dry 2-4 hours

Over coat 12-24 hours

Over coat 12-24 hours

Foot traffic – 24-48 hours

Foot traffic – 24-48 hours Cars 5 days

Cars 5 days Full hardness, scratch & chemical resistance – 7 days

Full hardness, scratch & chemical resistance – 7 days Product exhibits good chemical resistance with a high gloss easy clean

Product exhibits good chemical resistance with a high gloss easy clean Coating will fade and chalk in external applications

Coating will fade and chalk in external applications Suitable for heavy traffic Like cars, forklift trucks, vans and plant

Suitable for heavy traffic Like cars, forklift trucks, vans and plant Thinners suitable T0200 Universal Thinners

Thinners suitable T0200 Universal Thinners Covers Approx. 8 square metres per litre (this does not account for the method of application, absorption of substrate or wastage)

Covers Approx. 8 square metres per litre (this does not account for the method of application, absorption of substrate or wastage)

Multi Application suitable for Primed Metal, Concrete, Stone & Brick

Multi Application suitable for Primed Metal, Concrete, Stone & Brick

Make sure you use a mixer on a slow running drill, pallet knife or a broom stick that reaches the bottom of the can and mixing should take place for 3-5 mins to ensure all the content is properly mixed together to avoid colour and or drying problems.

Application

Step 1 - Check suitability of the product to the existing paint. We recommend you try a sample area first. Epoxies cannot be applied over single pack paints as they will attack the existing coating. Never pre seal the floor prior to painting especially with latex or PVC sealers paint will not stick.

Step 2 Clean and Abrade -

- Make sure the existing paint is in good condition prior to painting, then lightly abrade to provide a key for good intercoat adhesion.

- If there is flaking paint this must be removed prior to painting.

- Ensure substrate is dry and clean of any dirt, oil, or grease.

Step 3 Prime – Once you have completed the following steps you can apply this primer

Step 4 Topcoat- 12-24 hours later apply first coat of top coat.

Remember do not apply Two Pack Epoxy Paint in temperatures below 10 degrees centigrade cross linking of the paint and catalyst will not take place and the coating will never fully dry.

New Concrete Floors will need time to green this generally is a period of 3-6 months from when the concrete floor is laid, we say 3-6 months as it depends on the thickness of the concrete and quality, it’s always best ask the supplier and fitter of the concrete floor as to how long to wait till painting.

Always stir your paint up well prior to using

Make sure you use a broom stick, mixer on a slow running drill or pallet knife to mix and mixing should take place for 3-5 mins to ensure all the content is properly mixed together to avoid colour and or drying problems.

As our coatings are heavily pigmented separation can easily occur and you can have colour float, for example a green paint can seem blue before mixing, this is one of the reasons mixing your paint before use is essential.